|

Beeswax has been used since the beginning of civilization. It has been found in the pharaohs tombs, sunken viking ships and Roman ruins. Beeswax is basically the duct tape of old, with thousands of uses and being virtually indespensable.

Beeswax does not go bad and has been recovered from ancient ship wrecks heated up and is still usable. Over time beeswax gets what is called bloom. A light powdery substance that come out from within the wax. It is not mold and can be simply buffed off or left on for a nice patina on a candle etc..

HOW TO USE BEESWAX:

Pure beeswax is solid at room temperture. It will have a putty like consistancy at above 80-90 degrees F and will melt around 145-147 degrees F. Depending upon what you are using it for you may just let it sit in a bowl of hot tap water for a few minutes to allow it to turn into a putty like consistancy. To melt beeswax use a double boiler (a pot within a pot of water) this allows gentle heating which is important because beewax can burn rendering a browning hue and lose its aroma. Remember beewax is used in candle because it is flammable so be carefull near an open flame or a heat source. Do not exceed 160-170 degrees for any long period of time and you should fine.

HOW TO STORE BEESWAX:

As mentioned above beeswax never goes bad, but does get a powder called bloom on it. This usually happens when stored at cooler temperatures. A blow drier remove the bloom or just a soft rag to buff the bloom off.

Beeswax, being fairly soft and tacky has a tendency to pick up dust, dirt, fuzz etc.. Wrap in plastic to keep the dust off and store in a cool place. If it is too warm the wax can become soft and the plastic will stick or become embedded in the wax.

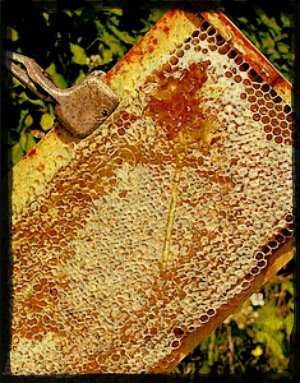

Beeswax cappings are used to cover the cells, these are removed to harvest the honey, we then melt down the cappings and filter the wax to make blocks of pure beeswax. It takes about 2 lbs of cappings to cover 100 lbs of honey. So you can see there is a lot of work the bees do to produce beeswax. Beeswax cappings are used to cover the cells, these are removed to harvest the honey, we then melt down the cappings and filter the wax to make blocks of pure beeswax. It takes about 2 lbs of cappings to cover 100 lbs of honey. So you can see there is a lot of work the bees do to produce beeswax.

Beeswax can now be used for a multitude of purposes. Beeswax is used in soap making, candle making, making cosmetics, lip balms, water proofing leather and wood as in boat building.

USES OF BEESWAX:

Cosmetics

Beeswax is the prime ingredient in lipbalms and indespensable in lotions and creams protecting and moisturizing skin. Also beeswax is used for hair styling. Beeswax is the long tradional ingredient in pomade, moustache wax and for condioning dread locks.

Woodworking

Beeswax is used as a wood finish also a wood polish, traditionally when added to odorless turpentine or boiled linseed oil. Beeswax has been long used as a lubricant coating screws and nails so they go in easier, also beeswax is applied to window sills and drawers to allow them to slide more smoothly.

ART WORK

Beeswax has been used in lost wax mold making since ancient times. This is where an object is carved out of beeswax the object is covered in clay then fired. The wax is melted in the process leaving a terracota mold that can now be cast by pouring molten metal into it.

Beeswax is used in encaustic art, this is when pigment is added to wax and to paint with vibrant colors. Beeswax is also used as a binder in beeswax collage and can be used to coat pictures in scrap booking for an antique look.

Beeswax is molded into a mouth peice for digeridoos.

Black Powder Shooting

Beeswax is added to tallow and used to lubricate lead bullets in black powder shooting. Cast wadcutter bullets have a band of wax to prevent leading the barrel of the gun.

Common Recipies

Wood Treatment

The most basic and commonly used is for butcher block or wood salad bowls etc. where the polish needs to be food grade. In a double boiler add 40% beeswax to 60% food grade mineral oil like what you find at the pharmacy. If it is still not the right consistency for your application you can just reheat and add more mineral oil to make the paste smoother.

For a wood finish for bare wood use a double boiler again add 1 lb Beeswax (1 pint melted) 1 pint turpentine (odorless preferably) and 1 pint boiled linseed oil.

| Q |

How much beeswax do I need? |

| A |

When melted 1 lb of beeswax become one pint. So one ounce by weight equals one fluid ounce. For larger projects there is 8 lbs per gallon melted. |

| Q |

What are some tips for candle making? |

| A |

Always use a double boiler to slowly warm the wax. This insures the wax doesn't burn or risks a fire hazard. We have had the best luck pouring candles where the wax is not too hot. Just over the melting point between 150 and 165 degrees. Hotter temperatures can cause cracking or can be difficult to release from the mold. We find silicon molds work the best to release candles because they stretch. Using mold release that is offered at most craft stores is also helpful, I have also heard of good results with cooking spray. |

Click Here for Beeswax

Click Here for Beeswax Recipes

|

Loading... Please wait...

Loading... Please wait... Loading... Please wait...

Loading... Please wait...